Fuel Injection System Plumbing Options

We often talk about the benefits of fuel injection on off-road vehicles. Generally, these systems run more reliably than carbureted systems, but they are, at the end of the day, a bit more complex than a carbureted fuel system. That's because almost all fuel injection systems require higher fuel pressures than a carbureted system, and most also require a fuel return line, not often found on a carbureted vehicle.

If you've built a rig from scratch or are upgrading an older vehicle to fuel injection, you will eventually need to learn how to make the fuel system work. After all, it's no longer as simple as hooking up a hose from the engine-driven (low-pressure) fuel pump to that fancy new EFI system. You will need a high-pressure pump (we prefer an in-tank, high-pressure pump) and quite possibly an entirely new fuel system to deal with the higher fuel pressures your system now requires. Also, you will probably need to add fuel filters (fuel injectors don't like dirt) and a fuel return line. There are many ways to accomplish this task. Here are a few methods we've used in the past and can recommend.

A vehicle's manufacturer almost always uses a hard metal line to run the long distance from the back of a 4x4 (where the tank usually is) to the front of the 4x4 (where the engine usually is). We like to duplicate this. Metal lines hold pressure very well and can withstand very high heat and abrasion. The trick is building a system that won't leak since we will have to have flexible connections between these metal lines and the fuel tank and the engine.

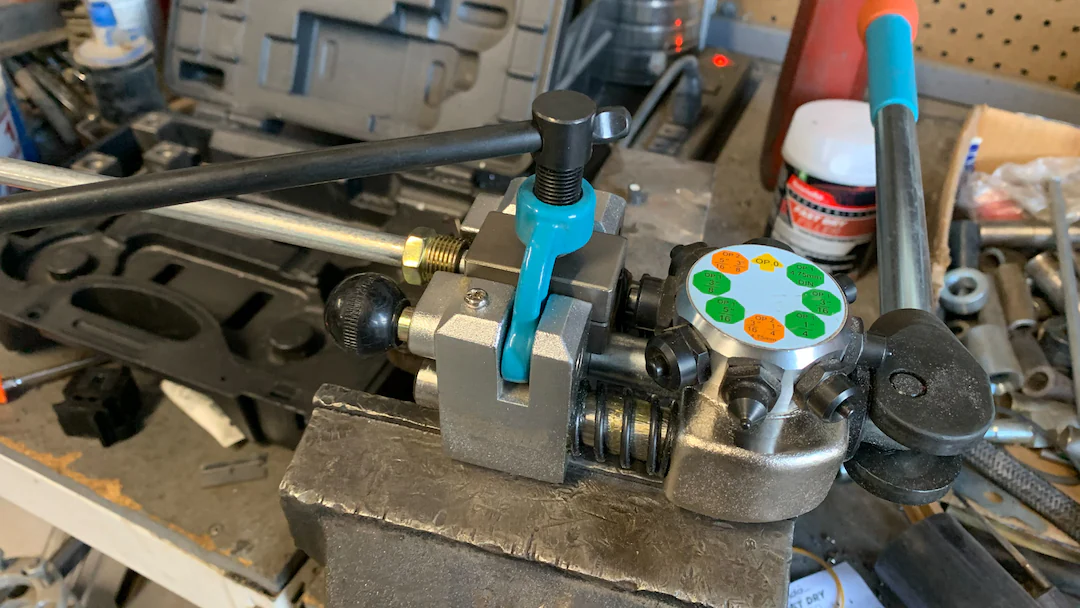

The easiest way to make hard metal lines (if your rig doesn't already have them) is to use a double flare tool and bendable lengths of hard metal line. You can then use double flare couplers to take the system to AN fittings to inverted double flare (like these and these) and either barbed fittings, push lock fittings, or in this case Earl's Vapor Guard fittings to make the transition from hard metal to rubber or flexible lines. If your vehicle had a carburetor and you are upgrading to EFI, you can use the factory hard metal line as the return line and build a high-pressure feed line to feed the system.

Fuel Line Sizing

Generally speaking, 3/8-inch fuel line is appropriate for most V-6, I-6, and V-8 engines and sometimes 5/16-inch will suffice for the smaller V-6s and I-6s. Likewise, you may want to go to 5/8 line and hose for a high-horsepower V-8. In AN hose speak, 3/8 ID hose converts to -6 sizing, -8 is for 5/8-inch ID and 1/2-inch ID hoses, and so on. For a four-cylinder you can get away with 5/16-inch hose and metal lines, maybe sometimes 1/4-inch for low-powered four-cyl engines. We wouldn't go smaller than -6 even if we used 5/16 flexible line as -4 is rated to 1/4-inch ID hoses and would restrict the system on a 5/16 fuel system.

Flexible Fuel Injection Hose Options

In the past we've built fuel systems for fuel injection (up to about 60-70 PSI) using one of three flexible hose systems.

Push Lock Hose

We've used push-to-lock hose and fittings, with parts paired by the hose manufacturer. This hose available via automotive supply houses like Summit Racing or your local hydraulic supply house uses a rubber hose with an internal weaved fabric to help it withstand higher pressures (generally around 300 psi). The metal fittings need to be paired with a hose from the same manufacturer. The hose can be a bear to push over the barbs of the metal fittings, but that's how the manufacturer gets these high-pressure ratings. Push lock can be used on other higher-pressure fluid systems like transmission coolant lines or power steering return lines. They should not be used on power steering feed lines.

Braided Fuel Hose

We've also used fuel hose that has either a nylon or stainless-steel outer weaving. This hose is cut to length with reusable fittings that come in a variety of configurations from straight to 90-degree bends. Assembly of the hose to the hose ends is a bit of work but doesn't require the brute force of push-lock-style hoses.

Braided hose is generally rated over 300psi and up to 350 psi (nylon) or 1,000 psi (stainless-steel) using the matching fittings. We've used Summit Racing's in-house brand of braided hose and fittings with success. Fittings look like this (black nylon) or this (stainless steel) and can be installed on a flush-cut length of matching hose. Braided hose can be used on other higher-pressure fluid systems like transmission coolant lines or power steering return lines. They should not be used on power steering feed lines unless rated to appropriate pressures.

Earl's Vapor Guard Fuel System for Fuel Injection

The Sniper fuel injection system that our Early Bronco BluePrint Engine's 306 has recommended Earl's Vapor Guard parts. The fittings are specific to the Earl's EFI Vapor Guard hose and use Earl's Vapor Guard Hose Clamps. Earl's does make Vapor Guard hose for carbureted applications that does not have the necessary pressure rating for EFI, so make sure you're getting the higher psi rated hose. The fuel injection system also recommends using a fuel filter that works with the Earl's Vapor Guard Hose and clamps (Holley PN: 562-1 or NAPA PN: 3482). This is the route we took for this vehicle.

comments 0